Oil-free water-cooled compressor: 38m³/h

Final output pressure: 50bar

Oil-free booster: 5 m³/h@liquid SF6

Vacuum pump: 64m³/h, ultimate vacuum 0.1mbar

Vacuum compressor: 31.3m³/h, ultimate vacuum 1mbar

Purification and refining tank: 220L, design pressure 50bar, stainless steel material

In the field of SF6 gas handling, the RF-101J SF6 purification and handling system has become the ideal choice for SF6 handling solutions with its cutting-edge technology and excellent performance.

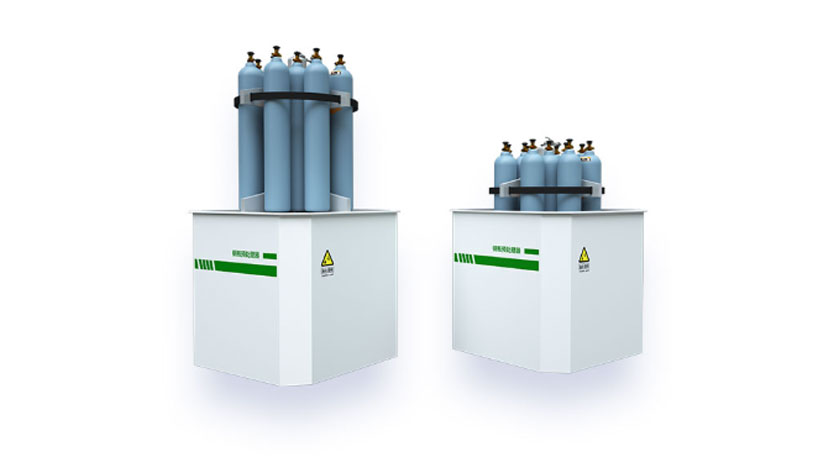

This SF6 purification and handling system is based on digital twin technology, SF6 gas deep purification and refining technology, automatic cylinder handling technology, and automatic cylinder storage technology. It realizes contactless and fully automatic processing of the entire process of SF6 gas recovery, purification, outbound, inbound, gas detection, filling, cylinder handling, etc., bringing you a one-stop convenient experience.

Main Features

-

Excellent Quality: The entire process of SF6 gas recovery, purification, filling, and storage is under strict control. The quality of the purified gas fully meets the requirements of the GB/T 12022 standard, eliminating your concerns about gas quality.

-

Efficient Recovery: The SF6 purification and handling system is equipped with a cylinder pre-handling device, which uses the water bath heating and vaporization method to significantly improve the gas recovery rate and save valuable time.

-

All-round Handling: The gas pre-handling device can easily handle the excessive SF6 decomposition gases in the waste gas, with comprehensive handling capabilities.

-

Rapid Handling: The gas buffer tank can store a large amount of SF6 gas, significantly improving the SF6 handling rate and work efficiency.

-

Regeneration Assurance: The system is equipped with a professional purification and refining device, effectively guaranteeing the quality of SF6 gas purification and regeneration, making the gas recycling more reliable.

-

Ultra-fast Filling: The SF6 purification and handling system has an SF6 liquid filling function. It only takes (5 - 8) minutes to fill a 40L cylinder with 50kg of SF6, which is highly efficient and convenient.

-

Intelligent Control: The intelligent cylinder storage device realizes digital control of the cylinder storage and distribution process, making management more accurate and efficient.

-

Flexible Operation: The SF6 purification and handling system adopts an advanced industrial control system, supporting touch screen operation throughout the process, and can also be remotely operated, which is convenient and intelligent.

-

Precise Detection: An embedded detection instrument can be optionally configured to accurately detect the purity, humidity, and decomposition products of SF6 gas, allowing you to keep abreast of the gas conditions in real time.

Choose the RF-101J SF6 purification and handling system, enjoy the convenience brought by digital control and intelligent storage, achieve efficient recycling of SF6 gas, and escort your SF6 gas handling work!

Product Parameters

| Parameter Name | Parameter Value |

|---|---|

| Oil-free water-cooled compressor | 38m³/h |

| Final output pressure | 50bar |

| Oil-free booster | 5m³/h@liquid SF6 |

| Vacuum pump | 64m³/h, ultimate vacuum 0.1mbar |

| Vacuum compressor | 31.3m³/h, ultimate vacuum 1mbar |

| Purification and refining tank | 220L, design pressure 50bar, stainless steel material |

| Rectification column | Deep purification, stainless steel material |

| Cooling method | Mechanical refrigeration |

| Cylinder pre-treatment device | Capable of handling 12@40L cylinders simultaneously, heating power 45kW |

| Gas pre-treatment device | Adopts water washing, alkali washing and cold drying process to treat toxic components in SF6 faulty gas |

| Gas buffer tank | 1000L, design pressure 50bar, carbon steel material |

| Intelligent cylinder storage repository | Capable of storing 380@40L gas cylinders, automatic access, digital management and control |

| Structural form | Closed type |

| Control method | 15-inch touch screen control and remote control |

| Power supply | Three-phase five-wire system, AC380V, 50Hz |